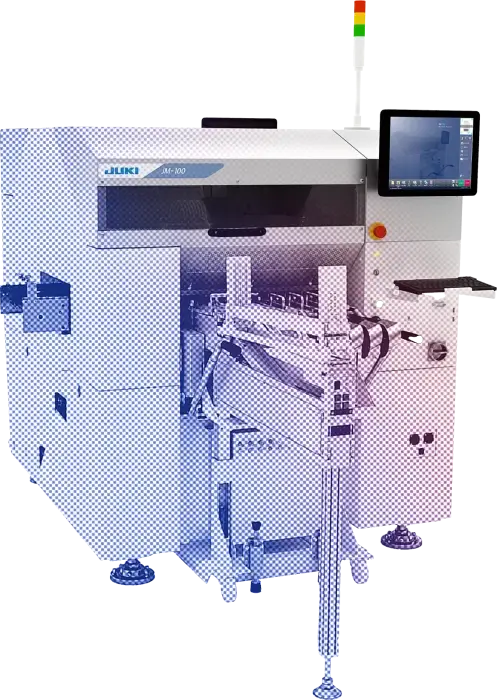

Highest quality and reliability

Trust in state-of-the-art technology!

- 3D Vision Centering System

- Firm connections guaranteed for a wide range of components

- Active clinching available

- Highest precision paired with high placement speed

- World market leader with more than 2000 machines sold worldwide (as of 2022)

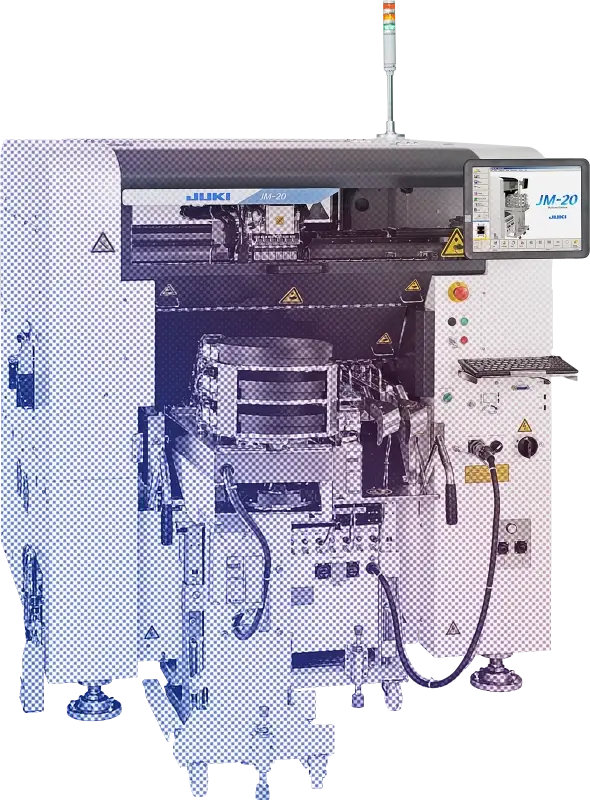

Automation and simple operation

State-of-the-art technology meets user-friendliness!

- Reduction of the human error rate

- Increased efficiency by reducing manual placement

- Automated function for component recognition

- Profitable even for the smallest production sizes

- Scalable up to full automation

Highest Flexibility

THT/SMD assembly for every application

- SMT and THT assembly in combination

- Solutions for High-Mix Low Volume

- Components of different types and special components are installed

- Various feeding options depending on requirements

- Unique, efficient placement head technology (patented Takumi head) for a wide range of components