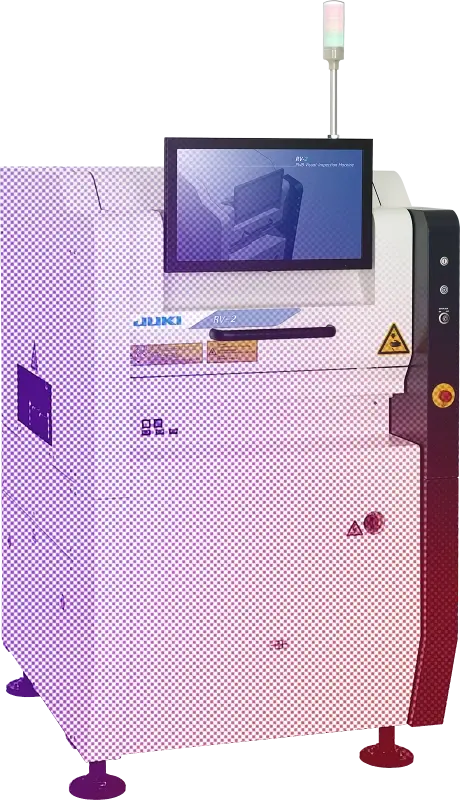

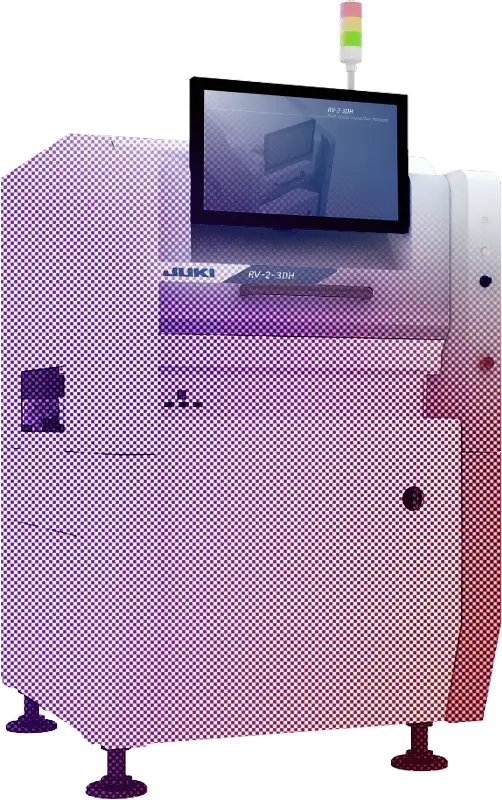

PCB handling and transport

PCB Size (L × W) min. 50 × 50 mm / max. 410 × 360 mm

PCB Weight max. 4.0 kg

Solder Pad Dimensions min. 01005 (inch) / max. 15 × 15 mm

PCB Feed Height 900 -20 / +70 mm

Measurable Solder Depot Properties

No / too little solder paste, print misalignment, depot volume, depot height, foreign objects etc.

Measurement System

Camera System 400 MPix CMOS

Measuring Principle i3D Photometric Stereo Technique

Measurement Resolution 15 µm / pixel (standard) / 10 µm / pixel (high resolution)

Field of View (FOV) 30 × 30 mm / 20 × 20 mm

Image Processing Speed 0.2 s / FOV

Machine Properties and Dimensions

Dimensions (L × W × H) 940 × 1276 × 1530 mm

Weight 1,000 kg

PC and Software

Operating System Windows 7, 64 bit

Interfaces SMEMA, OK / NG, USB, Ethernet

Operating Requirements

Power Supply 380 V, three phases

Compressed Air 5 bar

Ambient Conditions 15 – 30° C, 30 – 65 % RH

Standards (selection)

AWC, code recognition on PCB, true zero measurement reference, automatic calibration

Available Options and Accessories (selection)

Closed-Loop with screen paste printer, grid tools for supporting the PCB, TOPSS connection for remote analysis, long board option

Please refer to product specifications for details.

Specifications and design subject to change without notice.