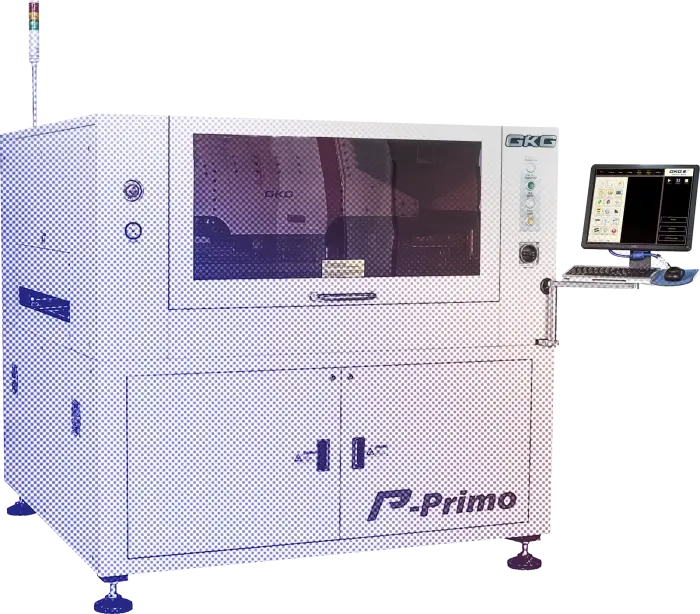

Worldwide proven printers of the highest quality "Outstanding quality confirmed worldwide!

Extremely stable machine design with cast frame and individually controllable squeegees

- No periodic machine calibration necessary

- CeTaQ-tested printing precision

- First choice of leading EMS service providers worldwide

Fully equipped, easy to maintain solder paste printers

Printing has never been so easy!

- Printing including 2D solder paste inspection and stencil inspection

- Automatic stencil cleaning

- Freely adjustable clamping of the PCB from above and from the side; vacuum also possible

- High ease of use thanks to intuitive graphical user interface with touch screen

- Uncomplicated and quick maintenance

Highest JUKI flexibility

Can be used variably and optionally expandable!

- Suitable for various PCB sizes (50x50 to 610x510 mm)

- Can be integrated into existing production lines - Closed loop interface for many well-known SPI manufacturers

- Adhesive dispenser

- Solder paste dispenser

- Automatic squeegee pressure monitoring

Award-winning technology

Productronica Innovation Award 2017

- Opti Paste Control (OPC) guarantees optimized paste consumption

- Quality Print Control (QPC)

- Increased level of automation for less user intervention during production

- Error reduction in the printing process